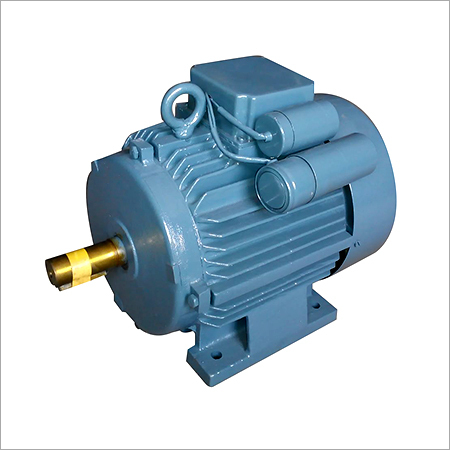

Industrial Electric Motors

Industrial Electric Motors Specification

- Bearing Type

- Heavy Duty Ball Bearing

- Noise Level

- <70 dB

- Ambient Temperature

- -15C to 50C

- Starting Type

- DOL

- Sealed Type

- Sealed Bearings

- Rated Voltage

- 415 V

- Efficacy

- IE2

- Horse Power

- 2 HP

- Current Type

- AC

- Power Rating

- 1.5 kW

- Poles Number

- 4

- Voltage

- 415 V

- Cooling Method

- Fan Cooled

- Standard

- IS 325

- Torque

- 10 Nm

- Features

- Robust construction, Low maintenance, Energy efficient

- Rated Frequency

- 50 Hz

- Motor Type

- Induction Motor

- Product Type

- Industrial Electric Motor

- Output Power

- 2 HP

- Frequency (MHz)

- 50 Hz

- Protect Feature

- Totally Enclosed Fan Cooled (TEFC)

- Phase

- Three Phase

- Speed

- 1440 RPM

- Power

- 1500 W

- Color

- Blue

- Dimension (L*W*H)

- 400 x 180 x 250 mm

- Weight

- 23 kg

- Shaft Diameter

- 28 mm

- Mounting Type

- Foot Mounted

- IP Rating

- IP55

- Duty Type

- S1 (Continuous)

- Rotor Type

- Squirrel Cage

- Insulation Class

- Class F

- Material

- Cast Iron Body

- Vibration Level

- Within Permissible Limit

- Enclosure

- TEFC

- Frame Size

- 112M

- Service Factor

- 1.15

- Temperature Rise

- Within Class F Limit

- Lubrication

- Grease Lubricated

- Direction of Rotation

- Both Directions

- Application

- Pumps, Compressors, Conveyors, Industrial Machinery

Industrial Electric Motors Trade Information

- Minimum Order Quantity

- 5 Pieces

- FOB Port

- ahemdabad

- Supply Ability

- 400 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- wooden boxes

- Main Domestic Market

- All India

- Certifications

- iso certified

About Industrial Electric Motors

We offer a comprehensive range of industrial electric motors. These motors are perfect for industrial / engineering applications. They are designed to be rugged, compact and energy-efficient. There is a right combination of reliable components and proven technology. The motors are simple, economical and dependable solution to your requirements. They incorporate excellent materials and design concepts. Also, there is good temperature range and perfect protection. The motors come in various sizes, capacities and specifications. We offer the right electric motor for your need. We supply the motors to manufacturing, power generation, construction, petrochemical, and industrial facilities.

Product details

| Power | 10 HP |

| Brand | Wilson |

| Speed | 2000 RPM |

| Type | AC |

| Usage/Application | Industrial |

| Phase | 3 |

| Material | Mild Steel |

| Voltage | 415 V |

| Mounting Type | Foot |

| Warranty | 1 Year |

| Country of Origin | Made in India |

Reliable Performance for Industrial Applications

This electric motor delivers consistent power output and is engineered for use with pumps, compressors, conveyors, and a broad range of industrial machinery. Its S1 duty type supports continuous operation, ensuring optimal productivity in demanding industrial environments. The sturdy cast iron body and TEFC enclosure guarantee protection against dust and water ingress, enabling long-term performance.

Enhanced Durability and Low Maintenance

With sealed heavy-duty ball bearings and a grease-lubricated system, this motor is designed to minimize upkeep while extending service life. The Class F insulation and permissible vibration levels help maintain temperature rise and noise below 70 dB, keeping both the motor and its surroundings stable and quiet. The robust construction conforms to IS 325 standards for quality assurance.

Energy Efficiency Redefined

Meeting IE2 efficiency standards, this induction motor offers significant energy savings while maintaining reliable torque delivery at 10 Nm. Its fan-cooled system and Class F temperature rise rating ensure dependable operation under extended use, making it an environmentally conscious and cost-effective choice for industrial facilities.

FAQs of Industrial Electric Motors:

Q: How should this electric motor be installed for optimal operation?

A: Install the motor in a well-ventilated area, mounted securely using its foot mounting on a flat, stable surface. Ensure proper alignment with pumps, compressors, or conveyors to minimize vibration and maximize efficiency. The direction of rotation can be set in either direction as per application needs.Q: What applications is this motor best suited for?

A: This motor is ideal for driving pumps, compressors, conveyors, and various industrial machinery due to its robust construction, continuous (S1) duty rating, and reliable performance across industrial sectors.Q: When is maintenance required for this motor, and what does it involve?

A: Regular inspection is recommended to check for any dust accumulation, bearing wear, or abnormal noise. As its equipped with grease-lubricated, sealed bearings, maintenance intervals are significantly extended, generally requiring only periodic verification unless used in harsh environments.Q: Where can this motor be used considering environmental factors?

A: Built with an IP55-rated TEFC enclosure, this motor is suitable for indoor and semi-outdoor industrial environments where exposure to dust or water is present. It operates reliably in ambient temperatures ranging from -15C to 50C, making it versatile for most climatic conditions in India.Q: What is the process for connecting the motor to an electrical supply?

A: The motor operates on a three-phase, 415 V, 50 Hz AC power supply. Follow standard wiring guidelines for Direct-On-Line (DOL) starting, ensuring all safety protocols and electrical standards (IS 325) are adhered to during installation for optimal safety and performance.Q: How does the Totally Enclosed Fan Cooled (TEFC) design benefit motor usage?

A: The TEFC enclosure protects internal components from dust and water, while the external fan ensures effective cooling during continuous operation. This reduces internal contamination and heat build-up, resulting in improved reliability and longer service life.Q: What are the advantages of the motors IE2 energy efficiency class?

A: The IE2 efficiency rating ensures the motor consumes less electrical power while delivering rated output, reducing overall operating costs and environmental impact. This makes it a smart investment for energy-conscious industrial facilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electric Motors Category

Pneumatic Electric Motors

Price Range 3100.00 - 7500.00 INR

Minimum Order Quantity : 5 Pieces

Voltage : 415 V

Poles Number : 4

Speed : 1440 RPM

Portable Electric Motors

Price Range 3100.00 - 7500.00 INR

Minimum Order Quantity : 5 Pieces

Voltage : 220 V / 415 V

Poles Number : Other, 2/4

Speed : 1440 RPM

Power Electric Motors

Price 1 INR / Piece

Minimum Order Quantity : 5 Pieces

Voltage : 415 V

Poles Number : 4

Speed : 1440 RPM

Flange Mounted Motor

Price 10000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 415 Volt (v)

Poles Number : 4

Speed : 1400 RPM

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free